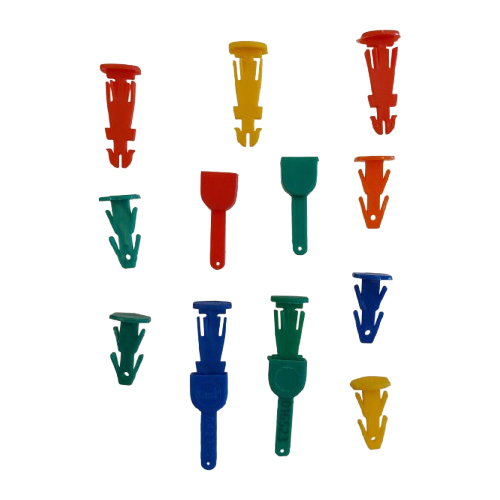

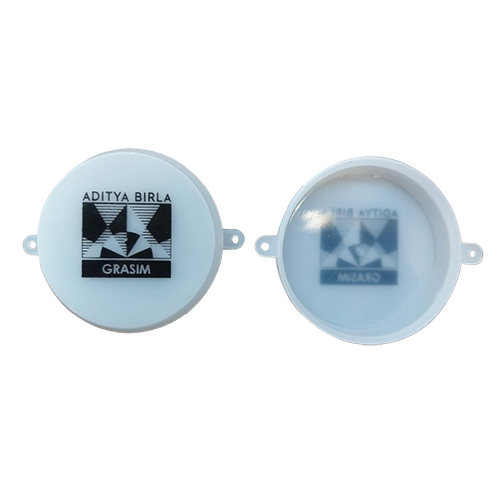

Trusted and Durable Drum Capseals, Crimping Tools, Drum

Bungs, Flanges, Security Seals, etc.

Incepted in 2007 in Mumbai, Maharashtra, Manthan Industries

is a trusted manufacturer, supplier, and trader of high-quality

industrial packaging and sealing solutions. With over a decade of

experience, we specialize in a comprehensive range of products including

Drum Capseals, Crimping Tools, Drum Bungs and Flanges, Security Seals,

and Drum Capsealing Machines.

Our products are engineered for durability, tamper resistance, and efficiency, serving the needs of chemical, pharmaceutical, oil, and logistics industries. At Manthan Industries, we focus on delivering precision, safety, and reliability in every component. Supported by a dedicated team of professionals and a strong focus on customer satisfaction, we consistently deliver high-quality products on time and at competitive prices. Our focus on continuous improvement and reliable service has earned us the trust of clients across India, making us a dependable choice in the industry.

Our Resources

At Manthan Industries, our manufacturing unit is the backbone of our operations, located in Mumbai, Maharashtra. Designed to support precision and efficiency, our facility is fully equipped to handle the production and assembly of industrial sealing and packaging components such as Drum Capseals, Crimping Tools, Drum Bungs and Flanges, Security Seals, and Drum Capsealing Machines.

Our infrastructure includes:

Our skilled workforce, combined with modern machinery, allows us to maintain strict quality control while meeting both bulk and customized order requirements. With a focus on efficiency, precision, and safety, we continually invest in technological upgrades to stay ahead in the industry.

Quality Checks

At Manthan Industries, quality is our utmost priority. We have implemented stringent quality control procedures throughout every stage of production to ensure that our products meet the highest standards of performance and safety.

Our quality checks include:

Our products are engineered for durability, tamper resistance, and efficiency, serving the needs of chemical, pharmaceutical, oil, and logistics industries. At Manthan Industries, we focus on delivering precision, safety, and reliability in every component. Supported by a dedicated team of professionals and a strong focus on customer satisfaction, we consistently deliver high-quality products on time and at competitive prices. Our focus on continuous improvement and reliable service has earned us the trust of clients across India, making us a dependable choice in the industry.

Our Resources

At Manthan Industries, our manufacturing unit is the backbone of our operations, located in Mumbai, Maharashtra. Designed to support precision and efficiency, our facility is fully equipped to handle the production and assembly of industrial sealing and packaging components such as Drum Capseals, Crimping Tools, Drum Bungs and Flanges, Security Seals, and Drum Capsealing Machines.

Our infrastructure includes:

- Hydraulic and Pneumatic Press Machines For shaping and forming capseals and flanges with high accuracy.

- Lathe Machines Used for precision machining of bungs and metallic components.

- Drilling and Milling Machines For crafting and finishing parts of crimping tools and sealing devices.

- Assembly Units Dedicated sections for manual and semi-automatic assembly of capseals, bungs, and sealing machines.

- Tool Room Equipment For maintenance and in-house fabrication of dies, jigs, and fixtures.

- Testing and Quality Control Setup Ensures each product meets durability, safety, and functional standards.

Our skilled workforce, combined with modern machinery, allows us to maintain strict quality control while meeting both bulk and customized order requirements. With a focus on efficiency, precision, and safety, we continually invest in technological upgrades to stay ahead in the industry.

Quality Checks

At Manthan Industries, quality is our utmost priority. We have implemented stringent quality control procedures throughout every stage of production to ensure that our products meet the highest standards of performance and safety.

Our quality checks include:

- Raw Material Inspection: All incoming raw materials are thoroughly tested for strength, composition, and compliance with industry standards before use.

- In-Process Monitoring: During manufacturing, each process is closely monitored by trained supervisors to maintain precision and consistency.

- Dimensional Accuracy: Using advanced measuring instruments, we verify the exact dimensions of drum capseals, bungs, flanges, and tools to ensure perfect fit and function.

- Durability and Strength Testing: Products undergo rigorous stress and pressure tests to guarantee long-lasting performance under demanding conditions.